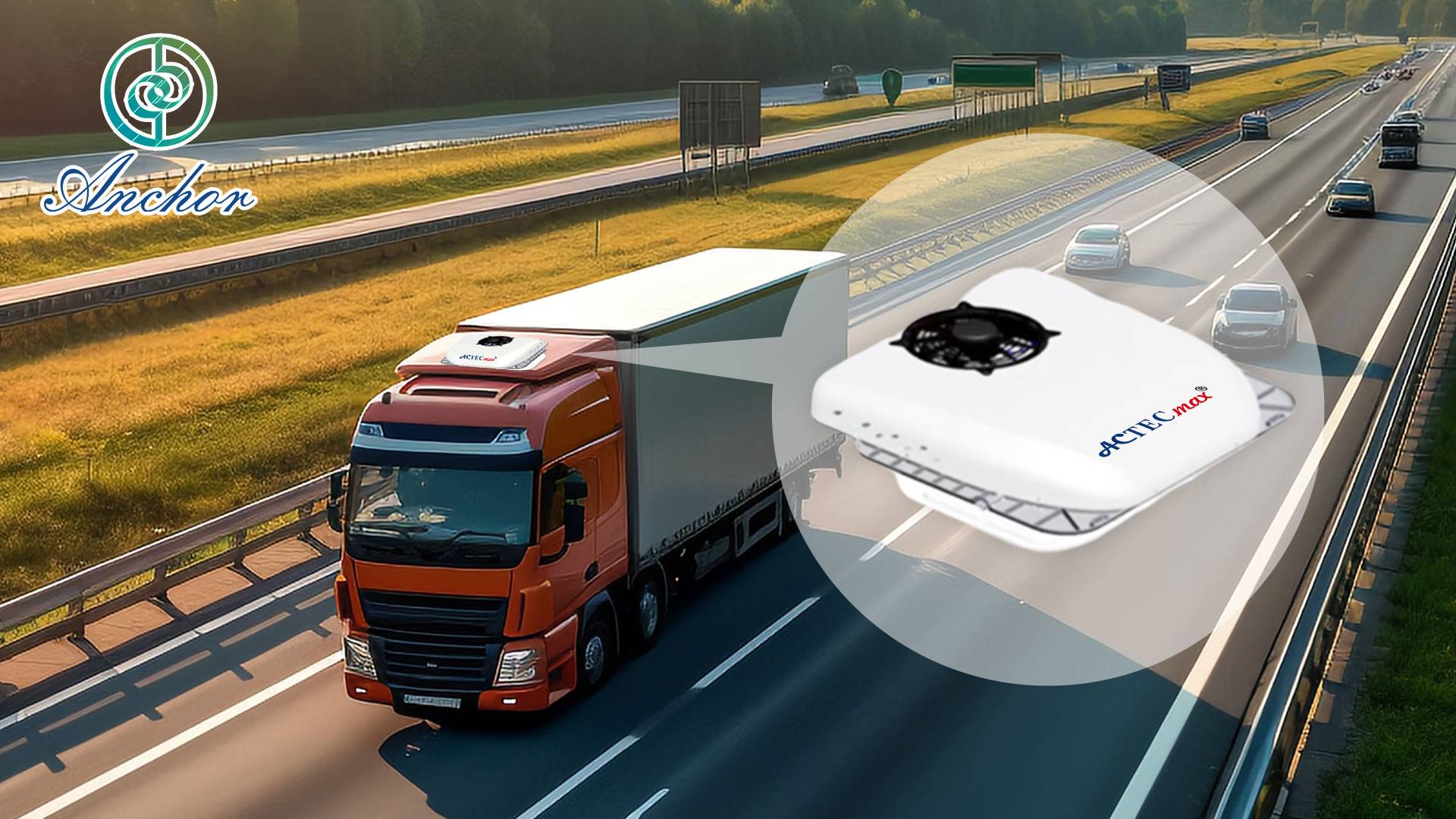

When it comes to long-haul trucking or spending extended hours in your truck, comfort is paramount. The scorching heat of the open road can be relentless, making a 12 volt air conditioner for trucks a necessity. Anchor Group has the perfect solution to keep truckers cool and comfortable during their journeys.

The Need for a 12 Volt Air Conditioner

Beat the Heat on the Road

Truck drivers often face challenging weather conditions while on the road. Whether it’s a sweltering summer day or a scorching desert highway, the heat can be unbearable. A 12 volt air conditioner for trucks ensures that you can stay cool and focused on your journey, no matter the weather outside.

Enhance Driver Well-Being

Extended exposure to high temperatures can lead to driver fatigue and discomfort. This not only affects the well-being of the driver but also their ability to perform their job effectively. Anchor Group’s 12 volt air conditioner helps combat these issues, promoting driver comfort and safety.

Anchor Group’s 12 Volt Air Conditioner for Trucks

Reliable Cooling

Anchor Group’s 12 volt air conditioner is designed with truckers in mind. It delivers reliable cooling performance, ensuring that the cabin stays comfortable even during the hottest days.

Easy Installation

Installation is a breeze with Anchor Group’s air conditioner. It comes with user-friendly instructions, allowing truckers to set it up quickly and get back on the road.

Conclusion

In conclusion, the 12 volt air conditioner for trucks by Anchor Group is the ultimate solution for truckers seeking comfort during their journeys. Beat the heat, enhance your well-being, and stay cool on the road with this reliable and easy-to-install air conditioner. Don’t let extreme temperatures hold you back; trust Anchor Group to keep you comfortable while you’re on the move.

The auto AC compressor clutch is a critical component of the air conditioning system that plays a vital role in maintaining a comfortable and cool environment inside your vehicle. It is essential to comprehend the functionality and significance of the AC compressor clutch to ensure optimal cooling performance. In this article, we will delve into the details of the AC compressor clutch, also known as the magnetic clutch or magnet clutch compressor, highlighting its role, benefits, and importance in the air conditioning system.

- What is an AC Compressor Clutch?

The AC compressor clutch is an electromechanical device located at the front of the air conditioning compressor. It consists of a pulley, hub, and an electromagnetic coil. When engaged, the clutch connects the compressor shaft to the engine’s belt drive system, allowing the compressor to operate and circulate refrigerant throughout the AC system.

- How Does the AC Compressor Clutch Operate?

The AC compressor clutch is activated by an electrical signal from the AC control system. When the air conditioning is turned on, the electromagnetic coil in the clutch receives power, creating a magnetic field. This magnetic field attracts the clutch plate, connecting it to the compressor shaft. As a result, the compressor begins to rotate, drawing in refrigerant from the evaporator and compressing it to generate cold air.

- Benefits of an AC Compressor Clutch:

- Enhanced Energy Efficiency: The AC compressor clutch allows the compressor to engage and disengage as needed, preventing unnecessary strain on the engine and improving overall energy efficiency. By operating only when necessary, the clutch reduces power consumption and enhances fuel economy.

- Extended Compressor Lifespan: The clutch’s ability to disengage the compressor when the air conditioning is not in use helps protect the compressor from excessive wear and tear. This prolongs the lifespan of the compressor and reduces the likelihood of costly repairs or replacements.

- Quick Cooling Response: The AC compressor clutch enables rapid cooling response by engaging the compressor instantly when the air conditioning is activated. This ensures that cool air is delivered promptly to the vehicle cabin, providing comfort even in hot weather conditions.

- Importance of Proper Maintenance:

To ensure the AC compressor clutch functions optimally, regular maintenance is crucial. Here are some maintenance tips to keep in mind:

- Check the clutch for signs of wear, such as unusual noises, slipping, or vibration. If any issues are detected, it is important to have the clutch inspected and repaired by a qualified technician.

- Keep the clutch and surrounding components clean and free from debris or contamination. Regular cleaning helps prevent clutch engagement issues and ensures smooth operation.

- Monitor the AC system’s refrigerant levels to prevent low refrigerant conditions, which can strain the compressor and affect the clutch’s performance.

Conclusion:

The auto AC compressor clutch is an integral part of the air conditioning system, responsible for engaging and disengaging the compressor as needed. Its role in enhancing energy efficiency, extending compressor lifespan, and providing quick cooling response cannot be overstated. Regular maintenance and prompt attention to any clutch-related issues are essential for ensuring optimal performance and a comfortable driving experience. By understanding the importance of the AC compressor clutch and its proper care, you can enjoy efficient cooling and long-lasting functionality from your vehicle’s air conditioning system.

Anchor Group boasts extensive experience in the production of Auto AC Compressor Clutche. With years of expertise in the automotive industry, we have established ourselves as a trusted manufacturer and supplier of high-quality compressor clutches. Our dedicated team of professionals possesses in-depth knowledge and skills in designing and manufacturing these essential components for air conditioning systems.

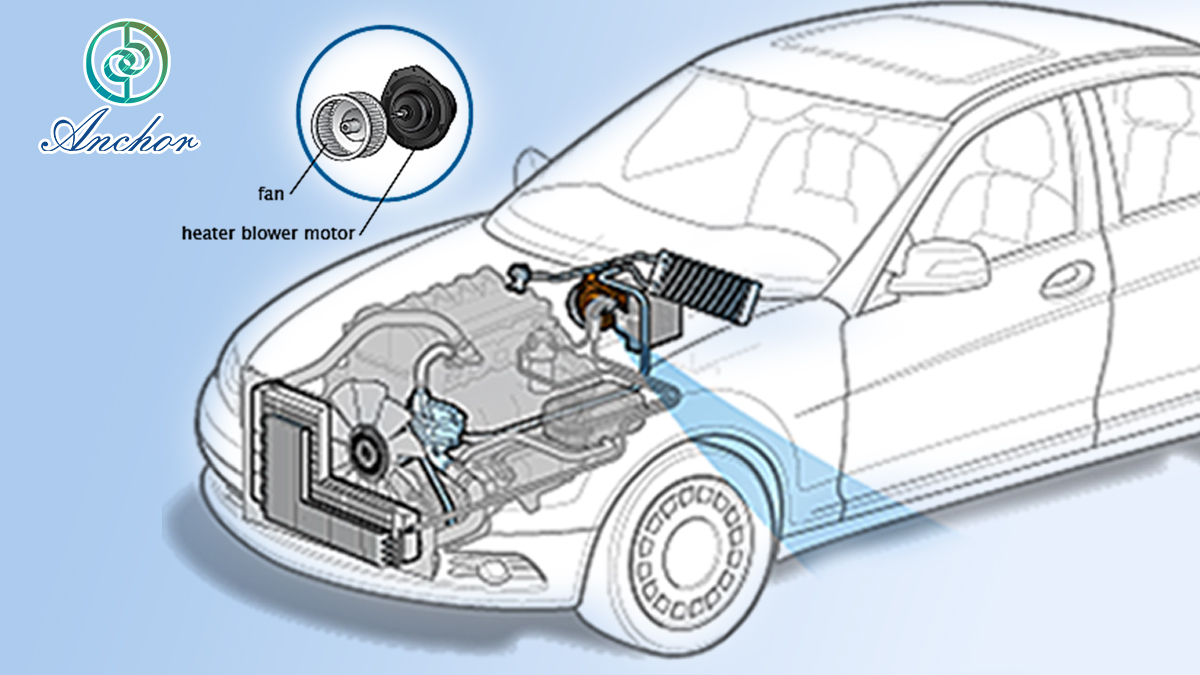

The auto AC system comprises various components that work together to provide cool and conditioned air inside the vehicle cabin. Two essential parts of this system are the evaporator and the blower motor. Let’s explore each of these components in more detail:

Auto AC Evaporator:

The evaporator is a heat exchanger located inside the vehicle’s cabin, typically behind the dashboard. Its primary function is to remove heat from the air and cool it down. The evaporator consists of a network of coils through which the refrigerant flows. As the refrigerant evaporates, it absorbs heat from the surrounding air, causing the air temperature to decrease significantly. This cooled air is then directed into the cabin through the vehicle’s vents, providing a comfortable environment for the occupants.

Blower Motor:

The blower motor is responsible for circulating the cooled air from the evaporator through the car’s ductwork and into the cabin. It is usually located behind the dashboard, close to the evaporator. The blower motor consists of a fan that pulls air from the cabin and pushes it over the evaporator coils. This action allows the air to absorb the coolness from the evaporator and distribute it throughout the vehicle. The blower motor also controls the speed of the fan, allowing the driver or passengers to adjust the airflow according to their preferences.

The blower motor is typically controlled by the HVAC (Heating, Ventilation, and Air Conditioning) system controls, which include switches, knobs, or electronic controls. These controls enable the user to adjust the fan speed, directing more or less air into the cabin, and regulate the overall cooling effect.

In summary, the auto AC evaporator and blower motor are integral components of the AC system. The evaporator cools the air by removing heat, while the blower motor circulates the cooled air throughout the vehicle’s cabin. Together, they ensure a comfortable and pleasant driving experience, especially during hot weather conditions. Regular maintenance and inspections are crucial to keep these components functioning optimally and to address any issues that may arise.

Anchor Group is a highly professional and experienced manufacturer in the production of auto Evaporator Blower Motors. With years of expertise in the automotive industry, we have established ourselves as a trusted name in delivering top-quality components for air conditioning systems. Our dedicated team of engineers and technicians possesses extensive knowledge and skills in designing and manufacturing Evaporator Blower Motors that meet the highest standards of performance and reliability.

Tractor cabins are essential workspaces for farmers and operators who spend long hours in the field. To enhance comfort and productivity, the installation of air conditioners in tractor cabs has become increasingly popular. These air conditioners help regulate the temperature, reduce humidity, and improve overall cabin conditions. Let’s explore the benefits and considerations of air conditioners for tractor cabs.

Benefits of Air Conditioners for Tractor Cabs:

1. Comfortable Working Environment: Operating a tractor in hot and humid weather can be extremely uncomfortable. Air conditioners provide a cool and pleasant environment inside the cab, allowing operators to focus on their tasks without the distraction of excessive heat.

2. Increased Productivity: A comfortable cabin temperature plays a significant role in maintaining the operator’s physical and mental well-being. By reducing fatigue and preventing heat-related issues, air conditioners contribute to increased productivity and efficiency during long working hours.

3. Operator Safety and Health: High temperatures and humidity levels can pose health risks to tractor operators. Air conditioners help regulate the cabin temperature, reducing the chances of heatstroke, dehydration, and other heat-related illnesses. They create a safer working environment, particularly during hot summer months or in regions with a tropical climate.

4. Protection of Electronic Equipment: Tractors are equipped with advanced electronic systems, including GPS navigation, telematics, and communication devices. These systems are susceptible to damage caused by excessive heat and humidity. Air conditioners help maintain a controlled temperature, ensuring the longevity and optimal performance of electronic equipment.

Considerations for Air Conditioners in Tractor Cabs:

1. Power Source: Tractors typically have their power supply, either from the tractor’s battery or an auxiliary power unit. When selecting an air conditioner, it is crucial to ensure compatibility with the tractor’s power source and electrical system. Some air conditioners are specifically designed for 12V or 24V systems commonly found in tractors.

2. Size and Installation: Tractor cabs vary in size and design, and it is important to choose an air conditioner that fits well within the available space. Compact and lightweight units are often preferred for easy installation and minimal impact on cabin ergonomics.

3. Cooling Capacity: The cooling capacity of an air conditioner should match the size of the tractor cab. It is important to consider factors such as the cab’s insulation, number of windows, and exposure to direct sunlight when determining the appropriate cooling capacity. Consulting with experts or manufacturers can help in selecting the right unit for specific tractor models.

4. Maintenance and Service: Regular maintenance is essential to ensure the proper functioning of the air conditioner. It is advisable to follow the manufacturer’s guidelines for cleaning filters, checking refrigerant levels, and servicing the unit. Additionally, access to service and support networks should be considered when choosing an air conditioner brand.

Conclusion:

Air conditioners for tractor cabs provide numerous benefits, ranging from operator comfort and productivity to the protection of electronic equipment. By creating a cool and controlled environment, these air conditioners contribute to a safer and more efficient working experience for tractor operators. When selecting an air conditioner, it is important to consider factors such as power source compatibility, size, cooling capacity, and maintenance requirements. With the right air conditioning solution, tractor operators can work comfortably and maximize their productivity in various weather conditions.

Anchor Group has amassed years of invaluable experience in manufacturing air conditioners specifically designed for tractor cabs. Their unwavering focus on quality and innovation has solidified their reputation as a trusted industry leader. Through extensive research and development, Anchor Group has fine-tuned their production processes to create high-performance air conditioners that cater to the unique needs of tractor operators. Collaborating closely with tractor manufacturers and industry experts, they have gained a deep understanding of cabin layouts and electrical systems, enabling them to design air conditioners that seamlessly integrate with a wide range of tractor models. With rigorous testing and quality assurance measures in place, Anchor Group ensures that each unit meets the highest standards of durability and performance. Tractor operators can confidently rely on Anchor Group’s expertise to provide them with reliable and long-lasting cooling solutions for their cabs.

https://www.acparts.cn/product-category/parking-cooler/

Introduction:

When it comes to long-haul trucking, maintaining a comfortable and pleasant cabin environment is crucial for drivers’ well-being and productivity. Anchor Group, with its extensive experience in manufacturing and researching 12 volt air conditioners for trucks, has emerged as a trusted provider in the industry. In this blog post, we will delve into Anchor Group’s years of expertise and explore the applications and advantages of 12 volt air conditioners for trucks.

I. Anchor Group’s Experience in 12 Volt Air Conditioners for Trucks:

1. A Legacy of Innovation: With a rich history in the automotive industry, Anchor Group has dedicated significant resources to develop cutting-edge cooling solutions for trucks. Their commitment to continuous research and development has allowed them to accumulate a wealth of knowledge and experience in the field of 12 volt air conditioners.

2. Collaboration with Industry Experts: Anchor Group collaborates closely with truck manufacturers, industry experts, and drivers to gain valuable insights into the unique cooling requirements of truck cabins. This collaboration ensures that their 12 volt air conditioners are specifically designed to meet the demands of long-haul trucking.

3. Rigorous Testing and Quality Assurance: Anchor Group’s state-of-the-art testing facilities and quality assurance processes guarantee that their 12 volt air conditioners meet the highest standards of performance, reliability, and durability. Each unit undergoes rigorous testing to ensure optimal cooling efficiency and long-term functionality in demanding trucking environments.

II. Applications of 12 Volt Air Conditioners for Trucks:

1. Comfortable Driving Experience: Long hours behind the wheel can be physically and mentally draining for truck drivers. 12 volt air conditioners offer a respite from the sweltering heat during summer months and help regulate cabin temperature, ensuring a comfortable driving experience. By maintaining a cool and pleasant environment, these air conditioners contribute to driver comfort and reduce fatigue.

2. Health and Well-being: Extreme temperatures can adversely affect driver health and well-being. Excessive heat and humidity can lead to dehydration, heat exhaustion, and decreased concentration. 12 volt air conditioners help mitigate these risks by keeping the cabin cool and reducing humidity levels, creating a healthier environment for drivers.

3. Protection of Cargo: Some cargo, such as perishable goods and temperature-sensitive products, require specific temperature conditions during transportation. 12 volt air conditioners for trucks help maintain a controlled climate inside the cabin, ensuring that the cargo remains in optimal condition throughout the journey.

4. Maintenance of Electronics: Modern trucks are equipped with various electronic devices and systems essential for communication, navigation, and tracking. Excessive heat can damage these sensitive electronics. 12 volt air conditioners assist in preventing overheating and prolonging the lifespan of these crucial systems, avoiding potential malfunctions and costly repairs.

III. Advantages of 12 Volt Air Conditioners for Trucks:

1. Compatibility with Truck Electrical Systems: 12 volt air conditioners are specifically designed to operate on the standard 12-volt electrical systems commonly found in trucks. This compatibility ensures seamless integration with the existing infrastructure, making installation and operation straightforward.

2. Energy Efficiency: 12 volt air conditioners are engineered for energy efficiency, minimizing the strain on the truck’s battery or auxiliary power source. They consume less power compared to traditional AC-powered units, allowing drivers to enjoy the benefits of cooling without significant impact on fuel consumption.

3. Compact and Space-Saving Design: Truck cabins have limited space, and 12 volt air conditioners are designed to maximize available room. These compact units can be installed without compromising the driver’s comfort or impeding their movement, making them an ideal solution for trucks of all sizes.

4. Durability and Resilience: Anchor Group’s 12 volt air conditioners are built to withstand the demanding conditions of the trucking industry. They are constructed with robust materials and incorporate features that enhance durability, such as resistance to vibrations, dust, and moisture. This ensures reliable operation and longevity, even in challenging environments.

5. Customization Options: Anchor Group offers a range of customization options for their 12 volt air conditioners to meet specific customer requirements. Whether it’s adjusting cooling capacity, incorporating additional features, or tailoring the design to fit the truck’s cabin, Anchor Group can provide personalized solutions to enhance driver comfort.

Conclusion:

Anchor Group’s years of experience in manufacturing and researching 12 volt air conditioners for trucks make them a trusted choice for the trucking industry. Through their commitment to innovation, collaboration, and rigorous testing, they have developed reliable and efficient cooling solutions that enhance comfort and well-being for truck drivers. The applications and advantages of 12 volt air conditioners extend beyond driver comfort, contributing to cargo protection, electronics maintenance, and overall operational efficiency. With Anchor Group’s expertise, truckers can rely on their 12 volt air conditioners to create a comfortable and productive environment while on the road.

With the increasing popularity of mobile lifestyles and the need for on-the-go cooling solutions, 12V air conditioners have emerged as a valuable option. These compact and versatile cooling systems are specifically designed to operate on a 12-volt DC power supply, making them ideal for use in vehicles, boats, RVs, camping, and other off-grid or mobile settings. This essay aims to delve into the features, applications, and benefits of 12V air conditioners, providing an in-depth understanding of their capabilities.

I. Understanding 12V Air Conditioners:

1. Power Source and Compatibility: 12V air conditioners are tailored to work seamlessly with the 12-volt DC electrical systems commonly found in vehicles, boats, and other portable setups. They can be directly powered by the vehicle’s battery or connected to a dedicated 12V power source, such as a portable power pack or solar panels. This compatibility ensures a convenient and reliable cooling solution while on the move.

2. Cooling Capacity and Efficiency: 12V air conditioners are designed to cool smaller spaces efficiently, such as the interior of vehicles, cabins, or small rooms. The cooling capacity can vary depending on the specific model, but most are optimized to provide effective cooling in confined areas. These air conditioners are engineered for energy efficiency, as they operate on low-voltage DC power, making them an excellent choice for environments with limited power supply.

3. Portability and Compact Design: One of the key advantages of 12V air conditioners is their portability. They are specifically designed to be lightweight, compact, and easy to transport. This feature allows users to install and remove them as needed, making them highly versatile for various applications and locations.

4. Installation and Mounting Options: Installing a 12V air conditioner is typically straightforward, and many models are specifically designed for temporary or portable use. They often come with mounting brackets, securing straps, or other installation accessories to ensure stability and ease of use. Depending on the specific model, installation may involve connecting the air conditioner to the vehicle’s electrical system or a separate power source.

5. Controls and Features: 12V air conditioners generally come with control panels or switches to adjust the temperature, fan speed, and other settings. Some models may also offer additional features such as timers, sleep modes, or adjustable vents to customize the cooling experience.

II. Applications of 12V Air Conditioners:

1. Vehicle Cooling: 12V air conditioners are commonly used in vehicles to provide cooling during hot summer months. They can effectively cool the cabin area, ensuring a comfortable driving experience for occupants. Whether it’s a car, truck, van, or recreational vehicle, these air conditioners offer relief from sweltering temperatures while on the road.

2. Boats and Marine Applications: Boats and other watercraft often lack traditional HVAC systems. 12V air conditioners offer a practical solution for keeping the cabin cool and comfortable while out on the water. They can help regulate temperatures, reduce humidity, and enhance overall comfort during boating trips or extended stays on board.

3. Camping and Outdoor Adventures: For outdoor enthusiasts, 12V air conditioners can be a game-changer. Whether camping in a tent or staying in a compact camper, these portable cooling units provide relief from the heat and humidity. They allow campers to enjoy a comfortable sleep environment and create a pleasant living space during their outdoor adventures.

4. Off-Grid Living and Remote Locations: Remote cabins, off-grid homes, and other locations without access to traditional power grids can benefit from 12V air conditioners. These cooling systems can be powered by alternative energy sources such as solar panels or dedicated battery banks. They offer a reliable and energy-efficient cooling solution for those seeking comfort in remote or self-sustaining living environments.

III. Benefits and Considerations:

1. Energy Efficiency and Low Power Consumption: 12V air conditioners are designed with energy efficiency in mind. They operate on low-voltage DC power, making them ideal for environments with limited power supply. These units consume less energy compared to traditional AC-powered air conditioners, which is particularly important when relying on batteries or alternative power sources.

2. Noise Level and Quiet Operation: As with any cooling system, noise level is an important consideration. While 12V air conditioners vary in noise output, many models are designed to operate quietly, ensuring a peaceful and comfortable environment.

3. Maintenance and Filter Cleaning: Regular maintenance and filter cleaning are essential for optimal performance and longevity of 12V air conditioners. Dust and debris can accumulate in the filters, hindering airflow and reducing cooling efficiency. It is important to follow the manufacturer’s guidelines for cleaning and maintenance to ensure consistent performance.

4. Consideration of Cooling Capacity: When selecting a 12V air conditioner, it is crucialto consider the cooling capacity required for the intended application. Factors such as the size of the space, insulation, and ambient temperatures should be taken into account to ensure the chosen unit is capable of meeting the cooling needs effectively.

5. Complementary Ventilation: While 12V air conditioners provide effective cooling, it’s important to consider ventilation as well. Proper airflow and ventilation can enhance the overall cooling performance. It is recommended to use the air conditioner in conjunction with open windows or vents to facilitate the circulation of cool air and the expulsion of hot air.

6. Battery Life Considerations: When using a 12V air conditioner with a vehicle or portable power pack, it’s essential to consider the impact on the battery life. Air conditioners can draw a significant amount of power, especially when operating at higher cooling settings. Monitoring the battery level and having a backup power source or a means to recharge the battery is advisable to prevent power depletion.

7. Climate Limitations: While 12V air conditioners can effectively cool smaller spaces, they may have limitations in extreme climates or excessively hot environments. In extremely high temperatures, the cooling capacity of these units may be reduced, and they may require additional support from other cooling methods, such as shade or insulation.

8. Durability and Weather Resistance: Since 12V air conditioners are often used in outdoor or mobile settings, it’s important to choose models that are built to withstand various environmental conditions. Look for air conditioners with durable construction, weather-resistant materials, and protective features to ensure longevity and reliable performance in different climates.

Conclusion:

12V air conditioners provide a convenient and portable cooling solution for a variety of applications. Their compatibility with 12-volt DC power systems, compact design, and efficient operation make them an excellent choice for vehicles, boats, camping, and off-grid living. By understanding their features, applications, and considerations, users can make informed decisions when selecting and utilizing 12V air conditioners to create comfortable and refreshing environments wherever they go.

Anchor Group is renowned for its exceptional expertise and professionalism in manufacturing 12V air conditioners. With a strong commitment to quality and innovation, Anchor Group has established itself as a leading provider in the industry. Their extensive knowledge and experience enable them to design and produce 12V air conditioners that meet the highest standards of performance, efficiency, and durability. From research and development to production and testing, every step of the manufacturing process is executed with meticulous attention to detail. Customers can trust Anchor Group to deliver reliable and top-notch 12V air conditioners that cater to a diverse range of applications, including vehicles, boats, camping, and off-grid living. With Anchor Group, you can be confident in their professionalism and dedication to excellence in the production of 12V air conditioners.

https://www.linkedin.com/company/automotive-air-conditioning-parts/?viewAsMember=true

Automotive AC hose fittings are connectors that join different sections of the air conditioning system’s hoses together. These fittings ensure a secure and leak-free connection between hoses, allowing the refrigerant to flow smoothly throughout the system. Automotive AC hose fittings come in various sizes, shapes, and types to accommodate different hose configurations and system requirements. Common types of fittings include:

1. O-ring fittings: These fittings have a built-in O-ring seal that creates a tight connection when the fittings are assembled.

2. Flare fittings: Flare fittings have a flared end that mates with a corresponding flared surface on the hose, creating a seal.

3. Quick disconnect fittings: These fittings allow for easy and quick disconnection of hoses for servicing or repairs.

4. Adapter fittings: Adapter fittings are used to connect hoses with different sizes or types of fittings, allowing for compatibility between different components of the AC system.

It’s important to choose the correct fittings that match the specific requirements of the AC system, including hose diameter, refrigerant type, and system pressure. Proper installation and sealing of AC hose fittings are essential to prevent refrigerant leaks and ensure the efficient operation of the car AC system. It’s recommended to consult the vehicle’s manufacturer specifications or seek professional assistance when working with auto AC hose fittings.

Anchor Group is a leading manufacturer of automotive AC hose fittings. With their expertise in the automotive industry, they specialize in producing high-quality fittings that meet stringent standards for performance and durability. Anchor Group’s commitment to precision engineering and advanced manufacturing techniques ensures that their AC hose fittings provide a reliable and leak-free connection in auto air conditioning systems. Whether it’s O-ring fittings, flare fittings, quick disconnect fittings, or adapter fittings, Anchor Group offers a wide range of fittings to cater to various hose configurations and system requirements. Their dedication to quality and customer satisfaction has made them a trusted choice for automotive AC hose fittings among professionals and enthusiasts alike.

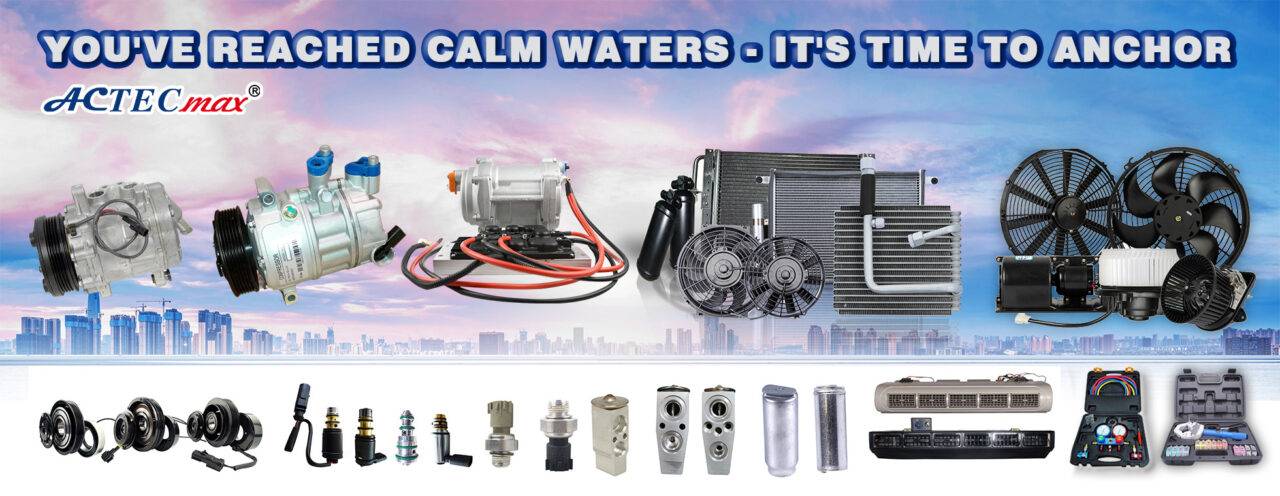

Automotive air conditioning systems consist of various components that work together to provide cooling and climate control inside a vehicle. Here are some common automotive air conditioning parts:

1. Compressor: The compressor is the heart of the air conditioning system. It compresses the refrigerant gas, raising its temperature and pressure before sending it to the condenser.

2. Condenser: The condenser is a heat exchanger located in front of the vehicle. It cools and condenses the high-pressure refrigerant gas into a liquid state by dissipating heat to the surrounding air.

3. Evaporator: The evaporator is typically located inside the vehicle’s cabin, often behind the dashboard. It absorbs heat from the cabin air, causing the refrigerant to evaporate and cool the air.

4. Expansion Valve or Orifice Tube: The expansion valve or orifice tube regulates the flow of refrigerant into the evaporator. It creates a pressure drop, allowing the refrigerant to expand and cool rapidly.

5. Receiver/Dryer or Accumulator: The receiver/dryer or accumulator is a container that removes moisture and filters debris from the refrigerant. It also stores excess refrigerant and ensures a steady flow to the expansion valve.

6. Refrigerant: Refrigerant is the working fluid used in automotive air conditioning systems. Commonly used refrigerants include R-134a and, in older systems, R-12. Refrigerants undergo phase changes from gas to liquid and back to gas, absorbing and releasing heat in the process.

7. Fans and Blowers: Fans and blowers help circulate air across the condenser and evaporator, aiding in heat exchange and distributing cooled air throughout the cabin.

8. Hoses and Pipes: Hoses and pipes connect various components of the air conditioning system, allowing refrigerant flow and facilitating the transfer of heat.

9. Pressure Switches and Sensors: Pressure switches and sensors monitor the pressure and temperature of the refrigerant at different points in the system. They provide feedback to the system’s control unit to ensure proper operation and protect against damage.

These are just some of the key components found in automotive air conditioning systems. Each part plays a crucial role in maintaining a comfortable and cool cabin environment for vehicle occupants.

Anchor Group is a professional company specializing in automotive air conditioning parts. They are known for providing high-quality components that meet the specific needs of the automotive industry.