When it comes to servicing and maintaining heating, ventilation, and air conditioning (HVAC) systems, HVAC manifold gauges are one of the most essential tools that technicians rely on. These precision instruments allow HVAC professionals to diagnose, troubleshoot, and perform maintenance on air conditioning and refrigeration systems. But what exactly are HVAC manifold gauges, and why are they so important?

What Are HVAC Manifold Gauges?

HVAC manifold gauges are tools designed to measure the pressure of refrigerants in HVAC systems, including air conditioners, refrigerators, and heat pumps. They consist of a set of two or three gauges and a set of hoses that connect to the refrigerant system. These gauges are typically color-coded and provide readings of both the high and low pressure within the system. By analyzing these readings, technicians can determine if the system is operating efficiently or if there are issues such as leaks, blockages, or overcharging.

Key Components of HVAC Manifold Gauges

An HVAC manifold gauge set typically consists of the following parts:

- High-Pressure Gauge: This gauge measures the pressure on the high side of the system, usually connected to the discharge side of the compressor.

- Low-Pressure Gauge: The low-pressure gauge measures the pressure on the low side, typically connected to the suction line of the system.

- Manifold Body: The manifold body contains valves that control the flow of refrigerant. It connects the gauges to the system and allows technicians to adjust and monitor pressure levels during diagnostics.

- Hoses: The hoses are used to connect the gauges to the system. They are typically color-coded—red for the high-pressure side, blue for the low-pressure side, and sometimes yellow for charging or evacuation.

- Valves: These are used to control the flow of refrigerant between the manifold and the system. The valves are usually operated by knobs or levers on the manifold body.

Types of HVAC Manifold Gauges

HVAC manifold gauges come in a few different varieties, each designed for specific applications:

- Analog Manifold Gauges: Traditional analog gauges use a dial to display pressure readings. They are simple to use and relatively inexpensive, making them a popular choice for technicians.

- Digital Manifold Gauges: Digital gauges provide a digital readout of pressure and often include additional features such as temperature compensation, refrigerant identification, and data logging. These are more expensive but offer greater precision and convenience for complex systems.

- Compound Manifold Gauges: These gauges can measure both positive and negative pressure, which is useful for systems that deal with a variety of pressure levels.

Importance of HVAC Manifold Gauges

HVAC manifold gauges are crucial for several reasons:

- Accurate Diagnosis: By measuring both the high and low pressures in an HVAC system, these gauges provide technicians with essential information for diagnosing issues such as low refrigerant levels, compressor failure, or clogged expansion valves.

- Efficient Maintenance: Proper pressure readings help technicians ensure that the HVAC system is running at optimal efficiency. Incorrect pressure levels can lead to energy inefficiency, which increases utility costs and wears down system components.

- Prevent System Damage: Monitoring refrigerant pressure can prevent damage to the compressor and other parts of the HVAC system. Overcharged or undercharged systems can cause undue stress on the components, leading to premature failure.

- Safe and Accurate Refrigerant Charging: Charging a system with the correct amount of refrigerant is crucial. HVAC manifold gauges help technicians determine how much refrigerant should be added, ensuring that the system is neither overcharged nor undercharged.

How to Use HVAC Manifold Gauges

Using HVAC manifold gauges is a straightforward process, but it requires careful attention to detail:

- Connect the Hoses: Attach the blue hose to the low-pressure side and the red hose to the high-pressure side of the system. If you’re using a yellow hose, connect it to the refrigerant cylinder.

- Check the Pressure: Start the HVAC system and observe the pressure readings on both the high and low-pressure gauges. Compare these readings to the manufacturer’s specifications for the particular system you are servicing.

- Diagnose the System: Based on the pressure readings, determine if the system is functioning correctly. If the pressures are outside the normal range, further inspection or adjustments will be necessary.

- Recharge or Evacuate the System: If the refrigerant levels are low, use the manifold to add refrigerant. If the system is overcharged, release some refrigerant to return the system to optimal pressure levels.

- Shut the System Down: After taking your readings and performing any necessary repairs or adjustments, close the manifold valves, and disconnect the hoses from the system.

Benefits of Using HVAC Manifold Gauges

- Precision in Diagnostics: Accurate pressure readings allow for precise troubleshooting, reducing the time needed for repairs.

- Increased System Lifespan: Proper maintenance and adjustments ensure the HVAC system operates efficiently, leading to a longer lifespan for both the system and its components.

- Energy Savings: By ensuring that the system is running at optimal pressure levels, HVAC manifold gauges help reduce energy consumption, ultimately saving on electricity costs.

HVAC manifold gauges are indispensable tools for any HVAC technician. They offer the precision needed to monitor, diagnose, and maintain HVAC systems efficiently. Whether you’re servicing a residential air conditioner, a commercial refrigeration unit, or a complex heat pump system, the accurate use of manifold gauges can save time, reduce costs, and extend the life of the equipment.

When selecting your HVAC manifold gauges, it’s important to choose the right model based on your specific needs. Depending on the system you’re working on, you may prefer an analog gauge for simplicity or a digital gauge for enhanced functionality.

These gauges are essential for anyone in the HVAC industry, whether you’re a seasoned professional or a newcomer. If you need HVAC manifold gauges or other HVAC tools, consider partnering with trusted suppliers to ensure that you have access to quality products that will help you perform your work efficiently and safely.

As temperatures rise, having a reliable air conditioning system in your car becomes essential. Among the various options available, Freon aircon for car systems have long been a preferred choice for their efficiency and cooling capabilities. In this blog, we’ll delve into what Freon aircon is, how it works, and why it might be the right choice for your vehicle. We’ll also cover how to recharge car AC.

What is Freon Aircon for Car?

Freon is a brand name for a class of chemicals used as refrigerants in air conditioning systems. The most common type used in automotive air conditioning systems is R134a, a hydrofluorocarbon (HFC) refrigerant. Freon works by cycling through the air conditioning system, absorbing heat from the car’s interior and releasing it outside, thereby cooling the cabin.

How Does Freon Aircon for Car Work?

A Freon-based air conditioning system operates through a series of stages:

- Compression: The compressor pressurizes the Freon gas, increasing its temperature.

- Condensation: The high-pressure, high-temperature gas moves to the condenser, where it releases heat and transforms into a high-pressure liquid.

- Expansion: The liquid refrigerant passes through an expansion valve, lowering its pressure and temperature.

- Evaporation: The low-pressure, cold liquid moves to the evaporator inside the car, where it absorbs heat from the cabin air and turns back into a gas.

- Circulation: The cycle repeats as the gas returns to the compressor, ensuring continuous cooling.

Benefits of Freon Aircon for Car

- Efficient Cooling: Freon aircon systems are known for their quick and effective cooling capabilities, making them ideal for hot climates.

- Reliability: These systems are robust and have a long service life with proper maintenance.

- Wide Availability: Freon refrigerants like R134a are widely available and supported by many service centers.

Environmental Considerations

While Freon aircon systems are effective, it’s essential to be aware of their environmental impact. HFCs like R134a are potent greenhouse gases. Efforts are ongoing to find more environmentally friendly alternatives, such as R1234yf, which has a lower global warming potential.

How to Recharge Car AC

Recharging your car’s AC system is a straightforward process that can improve cooling performance. Here’s how you can do it:

- Gather Supplies: You’ll need an AC recharge kit, which includes a can of refrigerant (R134a), a pressure gauge, and a hose.

- Locate the Low-Pressure Port: Find the low-pressure service port on your car’s AC system. It’s usually capped and located between the compressor and the evaporator.

- Connect the Recharge Kit: Attach the hose from the recharge kit to the low-pressure port. Ensure the connection is secure.

- Check the Pressure: Turn on the car and set the AC to the highest setting. Use the pressure gauge to check the current pressure in the system.

- Add Refrigerant: If the pressure is low, slowly add refrigerant to the system. Shake the can occasionally and keep the can upright while filling.

- Monitor the Pressure: Continue to add refrigerant until the pressure reaches the recommended level, which is usually marked on the gauge.

- Disconnect and Test: Once the system is recharged, disconnect the hose and replace the cap on the low-pressure port. Test the AC to ensure it’s cooling effectively.

Maintenance Tips

To keep your Freon aircon system in top shape, regular maintenance is crucial:

- Check for Leaks: Periodically inspect the system for leaks, as Freon can escape and reduce cooling efficiency.

- Recharge the System: If cooling performance drops, it might be time to recharge the system with additional refrigerant.

- Clean Components: Ensure the condenser and evaporator are clean to maximize heat exchange efficiency.

Conclusion

Freon aircon for car systems remain a reliable choice for many car owners, offering efficient and effective cooling. However, staying informed about maintenance and environmental considerations is key to ensuring long-term performance and sustainability.

About Anchor Group

At Anchor Group, we specialize in high-quality automotive air conditioning systems and components. Our products are designed to provide optimal performance and durability, ensuring your comfort on the road. With a commitment to innovation and customer satisfaction, Anchor Group is your trusted partner for all your automotive air conditioning needs. Visit our website or contact us today to learn more about our offerings.

Introduction

In the realm of ensuring passenger ease within buses, a dependable air conditioning system holds utmost significance. Among the prime selections for bus air conditioning units lies the Carrier air conditioner. This discourse will delve into the characteristics, merits, installation procedure, maintenance guidelines, and prevalent issues associated with Carrier air conditioners for buses.

Understanding Carrier AC

What Sets Carrier AC Apart?

Carrier air conditioners garner acclaim for their extraordinary cooling efficacy, energy conservation, and endurance. Tailored specifically for buses, Carrier AC units boast advanced technologies to deliver unwavering cooling even amidst extreme climatic conditions.

Benefits of Carrier AC for Buses

Carrier air conditioners present myriad advantages for both bus operators and passengers alike. From sustaining a pleasant interior temperature to curbing fuel consumption, here are some pivotal benefits:

- Efficient Cooling: Carrier AC units furnish robust cooling performance, ensuring passenger comfort even amidst scorching summer days.

- Energy Efficiency: Equipped with cutting-edge compressor technology, Carrier AC units curtail energy utilization, thus leading to diminished operational expenses for bus operators.

- Endurance: Crafted to endure the rigors of day-to-day bus operations, Carrier AC units exhibit resilience and longevity, thereby lessening the necessity for frequent replacements.

- Tranquil Operation: Carrier AC units operate silently, furnishing a serene ambiance for passengers to unwind during their journey.

Installation Process

A Step-by-Step Manual to Installing Carrier AC

Embedding a Carrier air conditioner in a bus mandates meticulous planning and execution. Below delineated is a stepwise guide to the installation process:

- Preparation: Evaluate the bus layout and ascertain the optimum placement for installing the AC unit.

- Mounting Bracket Installation: Securely affix the mounting brackets onto the bus roof, ensuring precise alignment and reinforcement.

- AC Unit Placement: Situate the Carrier AC unit onto the mounting brackets and secure it firmly in position using bolts and screws.

- Electrical Wiring: Establish the connection of the AC unit to the bus’s electrical system, ensuring adequate grounding and insulation to avert electrical hazards.

- Testing: Upon the completion of installation, conduct a comprehensive test to verify the proper functionality of the AC unit and its provision of adequate cooling.

Maintenance Tips

Safeguarding Longevity and Optimal Performance

Safeguarding the longevity and peak performance of your Carrier air conditioner necessitates regular upkeep. Presented herewith are some maintenance pointers to bear in mind:

- Routine Cleansing: Regularly purge the air filters, condenser coils, and evaporator coils to eliminate dust, debris, and other contaminants.

- Leak Inspection: Periodically inspect for refrigerant leaks and promptly rectify them to forestall the diminishment of cooling efficiency.

- Lubrication: Apply lubrication to the mobile components of the AC unit to mitigate friction and wear, thereby ensuring seamless operation.

- Professional Servicing: Schedule annual maintenance inspections with a certified technician to scrutinize and service the AC unit for any potential issues.

Common Predicaments and Resolutions

A Troubleshooting Manual for Carrier AC

Despite their reliability, Carrier AC units may occasionally encounter predicaments. Presented below are some prevalent issues along with their resolutions:

- Inadequate Cooling: Examine the air filters and condenser coils for grime and debris, and cleanse or replace them as required. Ensure unimpeded airflow by eliminating any obstructions around the AC unit.

- Unusual Noises: Inspect the fan blades and motor for indications of damage or wear. Tighten any loose components and lubricate mobile parts to diminish noise.

- Electrical Hitches: Scrutinize the electrical connections for loose or corroded terminals. Assess the voltage and current levels to ensure proper functionality.

- Refrigerant Leaks: In the event of suspecting a refrigerant leak, conduct a leak test utilizing a refrigerant leak detector and mend any detected leaks. Replenish the system with the appropriate quantity of refrigerant.

FAQs

Answers to Common Queries

- How do I ascertain the appropriate Carrier air conditioner for my bus? To determine the suitable Carrier AC unit for your bus, deliberate upon factors such as bus dimensions, passenger capacity, and cooling requisites. Seek counsel from a qualified HVAC technician for personalized recommendations.

- What is the warranty coverage for Carrier AC units? Carrier extends warranty coverage for its air conditioning units, typically spanning from one to five years contingent upon the model and purchase terms. It is imperative to peruse the warranty particulars provided by the manufacturer.

- Can I install a Carrier AC unit on any bus type? Carrier air conditioners are devised to harmonize with diverse bus models and configurations. Nonetheless, it is imperative to ascertain that the chosen AC unit is compatible with your specific bus type and dimensions.

Conclusion

In summation, investing in a Carrier air conditioner for your bus can markedly elevate passenger comfort and contentment. Endowed with efficacious cooling performance, energy efficiency, and resilience, Carrier AC units proffer a dependable solution for bus operators. By adhering to proper installation, maintenance, and troubleshooting protocols, you can ensure optimal performance and longevity of your Carrier air conditioner.

Anchor Group: Your premier source for top-tier OEM and aftermarket AC components and tools for a broad spectrum of vehicles. Explore our extensive range of wholesale automotive air conditioning parts, auto AC fittings, aftermarket truck air conditioners, and automotive AC condensers in varied sizes, including Carrier bus air conditioning systems.(https://www.acparts.cn/product-category/bus-air-conditioning/)

Reference: OneStopACParts – Bus Air Conditioning System

Introduction

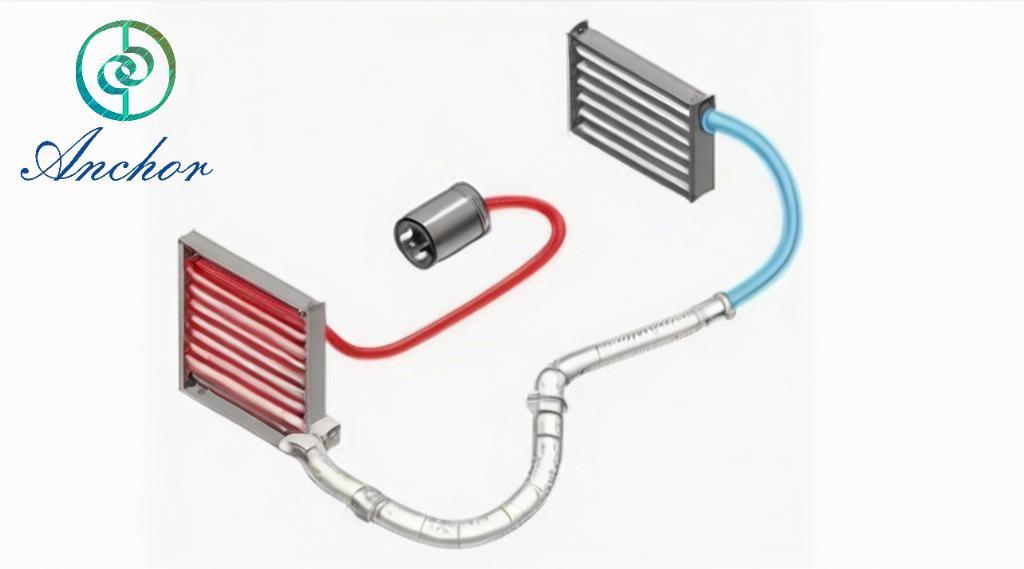

Auto air conditioning hoses play a vital role in the functioning of a vehicle’s air conditioning system. They are responsible for carrying refrigerant, allowing it to circulate between the various components of the AC system, ensuring optimal cooling performance. Understanding the significance of these hoses and how to maintain them is crucial for every vehicle owner.

Understanding Auto Air Conditioning Hoses

What Are Auto Air Conditioning Hoses?

Auto air conditioning hoses are flexible tubes made of rubber or aluminum. They connect various components of the vehicle’s AC system, such as the compressor, condenser, evaporator, and receiver-drier or accumulator. These hoses transport refrigerant throughout the system, facilitating the cooling process inside the vehicle.

The Role of Auto Air Conditioning Hoses

Auto air conditioning hoses serve as conduits for refrigerant, allowing it to flow from one component to another within the AC system. Without these hoses, the refrigerant would not be able to reach the necessary parts for cooling, leading to a malfunctioning AC system.

Selecting the Right Auto Air Conditioning Hose

Factors to Consider When Choosing Auto Air Conditioning Hoses

When selecting auto air conditioning hoses, several factors need to be taken into account to ensure compatibility and optimal performance.

1. Material Composition

Auto air conditioning hoses are typically made of either rubber or aluminum. Each material has its advantages and is suited for specific applications. Rubber hoses are flexible and durable, while aluminum hoses offer superior heat dissipation.

2. Compatibility

It’s essential to choose hoses that are compatible with the refrigerant used in your vehicle’s AC system. Using incompatible hoses can lead to leaks or system damage.

Maintaining Auto Air Conditioning Hoses

Tips for Maintaining Auto Air Conditioning Hoses

Proper maintenance of auto air conditioning hoses is essential for ensuring the longevity and efficiency of your vehicle’s AC system.

1. Regular Inspection

Periodically inspect the condition of the hoses for signs of wear, damage, or leaks. Look for cracks, bulges, or soft spots that may indicate deterioration.

2. Keep Hoses Clean

Ensure that the hoses remain free of dirt, debris, and oil buildup, as these can accelerate wear and compromise performance. Clean the hoses regularly using a mild detergent and water.

Common Issues with Auto Air Conditioning Hoses

Identifying and Addressing Common Problems

Despite their durability, auto air conditioning hoses can experience issues over time. Being aware of common problems can help you address them promptly.

1. Leaks

Leaks are one of the most common issues with auto air conditioning hoses. They can occur due to wear and tear, corrosion, or improper installation. Leaks can lead to a loss of refrigerant and diminished cooling performance.

2. Damage from External Factors

Auto air conditioning hoses are exposed to various external factors, such as heat, vibration, and road debris, which can cause damage over time. Protecting the hoses and conducting regular inspections can help prevent damage.

FAQs (Frequently Asked Questions)

How often should auto air conditioning hoses be inspected? Auto air conditioning hoses should be inspected at least once a year or whenever you notice any signs of damage or deterioration.

Can I repair a leaking auto air conditioning hose myself? While minor leaks may be repairable using patch kits, it’s recommended to have leaks professionally repaired to ensure proper sealing and prevent future issues.

What are the signs of a failing auto air conditioning hose? Signs of a failing auto air conditioning hose include reduced cooling performance, hissing noises from the AC system, visible leaks, and unusual odors.

Are aftermarket auto air conditioning hoses as reliable as OEM ones? Aftermarket auto air conditioning hoses can be just as reliable as OEM ones if they meet the necessary quality standards and specifications.

How long do auto air conditioning hoses typically last? The lifespan of auto air conditioning hoses can vary depending on factors such as usage, maintenance, and environmental conditions. On average, they can last anywhere from five to ten years.

Is it necessary to replace all auto air conditioning hoses at once? While it’s not always necessary to replace all hoses simultaneously, it’s recommended to replace them in sets or as needed to maintain the integrity of the AC system.

Conclusion

Auto air conditioning hoses are integral components of a vehicle’s AC system, responsible for circulating refrigerant and facilitating cooling. By understanding their importance, selecting the right hoses, and implementing proper maintenance practices, you can ensure optimal performance and longevity of your vehicle’s AC system.

https://www.acparts.cn/product-category/hoses/

Enhancing Sustainability with No Idle Air Conditioners

No idle air conditioners represent a revolutionary advancement in vehicle cooling technology. These innovative systems offer a sustainable solution to the traditional practice of engine idling for climate control. By eliminating the need for idling, no idle air conditioners reduce fuel consumption, minimize emissions, and extend the lifespan of the vehicle’s engine. In this comprehensive guide, we explore the benefits, applications, and considerations associated with no idle air conditioners.

Understanding No Idle Air Conditioners

No idle air conditioners, also known as idle-free HVAC systems, are designed to provide climate control to vehicles without requiring the engine to idle. These systems operate independently, utilizing auxiliary power sources such as batteries or shore power. By doing so, they eliminate the need for engine idling while still ensuring optimal cooling performance. No idle air conditioners are suitable for various vehicle types, including commercial trucks, buses, and recreational vehicles.

Benefits of No Idle Air Conditioners

1. Environmental Impact

No idle air conditioners significantly reduce greenhouse gas emissions and air pollution by eliminating engine idling. This makes them an environmentally friendly choice, contributing to cleaner air and a healthier planet.

2. Fuel Efficiency

By minimizing or eliminating engine idling, no idle air conditioners help conserve fuel, leading to cost savings for vehicle owners and operators. This improved fuel efficiency benefits both individual drivers and fleet operators.

3. Engine Longevity

Prolonged engine idling can contribute to wear and tear on vital engine components. No idle air conditioners help preserve engine integrity by reducing idling, resulting in fewer maintenance issues and extended engine lifespan.

4. Comfort and Convenience

No idle air conditioners provide consistent and reliable climate control to occupants, even when the vehicle is stationary. This ensures passenger comfort and convenience without the noise and vibration associated with engine idling.

Applications of No Idle Air Conditioners

1. Commercial Fleets

Fleet operators benefit greatly from the adoption of no idle air conditioners. These systems help reduce fuel costs, minimize emissions, and improve overall operational efficiency, making them an attractive option for businesses with large vehicle fleets.

2. Recreational Vehicles

No idle air conditioners are popular among recreational vehicle owners who value comfort and sustainability during their travels. These systems allow RV enthusiasts to enjoy climate-controlled interiors without relying on the vehicle’s engine.

3. Emergency Vehicles

Emergency response vehicles, such as ambulances and fire trucks, rely on no idle air conditioners to maintain optimal conditions for patients, medical equipment, and personnel. These systems ensure a comfortable environment without compromising vehicle readiness.

Choosing the Right No Idle Air Conditioner

When selecting a no idle air conditioner, consider factors such as cooling capacity, power source compatibility, installation requirements, and manufacturer reputation. It’s essential to choose a system that meets the specific needs of your vehicle and operation.

Conclusion

No idle air conditioners offer a sustainable and efficient solution to vehicle climate control, benefiting both the environment and vehicle owners. By eliminating the need for engine idling, these systems reduce emissions, conserve fuel, and enhance engine longevity. Whether for commercial fleets, recreational vehicles, or emergency services, no idle air conditioners provide comfort, efficiency, and peace of mind.

https://www.acparts.cn/product-category/parking-cooler/

In the logistics industry, the question of how much does a refrigerated truck cost is a crucial consideration for businesses aiming to transport temperature-sensitive goods. This comprehensive guide will delve into various aspects, providing insights into the factors influencing costs, different sizes available, and additional features that may impact the overall expense.

Factors Influencing Refrigerated Truck Costs

Size Matters: Navigating the Dimensions

Understanding the correlation between size and cost is pivotal. Larger refrigerated trucks typically come with a higher price tag due to increased capacity. Smaller trucks offer a cost-effective solution for businesses with moderate transportation needs.

Cooling Technologies: A Look into Options

Exploring diverse cooling technologies is essential. From traditional mechanical systems to advanced electric options, the chosen technology can significantly impact the overall cost. Finding the right balance between efficiency and affordability is key.

Brand Reputation: The Price of Reliability

The reputation of the brand plays a crucial role. Established brands with a history of reliability may command a higher cost, but the assurance of quality and durability often justifies the investment in the long run.

How Much Does a Refrigerated Truck Cost?

Understanding the price range is vital for businesses planning their budget.

Entry-Level Options

Entry-level refrigerated trucks start at around $40,000, catering to businesses with moderate transportation needs. These trucks offer a balance between affordability and functionality.

Mid-Range Investments

For businesses with larger cargo requirements, mid-range refrigerated trucks in the $70,000 to $100,000 range provide a reliable solution. These trucks offer a balance between capacity and affordability.

Premium Choices

Premium refrigerated trucks, starting at $120,000, are designed for enterprises requiring top-notch features and expansive capacity. These high-end options often come with advanced technology and superior build quality.

Frequently Asked Questions (FAQs)

What Maintenance is Required for Refrigerated Trucks?

Regular maintenance is crucial to ensure optimal performance. This includes checking the cooling system, inspecting insulation, and monitoring temperature control systems.

Are There Financing Options Available for Purchasing Refrigerated Trucks?

Yes, many dealerships and financial institutions offer financing options for purchasing refrigerated trucks. It’s advisable to explore these options to ease the financial burden.

Can I Retrofit an Existing Truck into a Refrigerated Truck?

Retrofitting is possible, but it’s essential to consult with professionals to ensure the proper installation of cooling systems and insulation for effective temperature control.

What Impact Does Fuel Type Have on Operating Costs?

The fuel type can influence operating costs. While diesel may offer higher efficiency, electric options are gaining popularity for their eco-friendly and cost-effective features.

Are There Government Incentives for Purchasing Eco-Friendly Refrigerated Trucks?

Some regions offer incentives or tax credits for businesses investing in eco-friendly refrigerated trucks. Researching local regulations can help uncover potential benefits.

How Long Does a Refrigerated Truck Typically Last?

With proper maintenance, a refrigerated truck can last up to 15 years or more. However, regular inspections and timely repairs are essential to prolong its lifespan.

Conclusion

Navigating the landscape of refrigerated truck costs involves understanding the interplay of size, cooling technology, and brand reputation. By aligning your investment with your business needs, you can make an informed decision that ensures efficiency, reliability, and longevity.

Explore the diverse range of refrigerated trucks available, weigh the costs against the benefits, and make a decision that propels your business towards success in temperature-sensitive logistics.

https://www.acparts.cn/product/ac-133-070-refrigerated-truck-units/

Embarking on a camping adventure doesn’t mean sacrificing comfort. In this guide, we delve into the world of tent air conditioners, unlocking the secrets to staying cool and comfortable in the great outdoors. Whether you’re a seasoned camper or a novice explorer, our comprehensive insights will elevate your camping experience.

Understanding Tent Air Conditioners

Introduction to Tent Air Conditioners Explore the innovative world of tent air conditioners and how they revolutionize camping comfort. Uncover the technology that brings cool relief to your tent, making camping a breeze even in the hottest weather.

Why Choose a Tent Air Conditioner? Discover the undeniable benefits of opting for a tent air conditioner. From beating the summer heat to ensuring a good night’s sleep, these portable devices are your ticket to a refreshing camping experience.

Essential Features for Comfort

Portability at Its Finest Explore the compact and lightweight design of tent air conditioners, making them easy to carry and set up at your campsite. Experience cool comfort without the burden of heavy equipment.

Battery Efficiency Delve into the energy efficiency of tent air conditioners. Learn how they optimize battery usage, ensuring you stay cool throughout your camping trip without worrying about power consumption.

Setting Up Your Tent Air Conditioner

Choosing the Right Location Get insights into selecting the perfect spot for your tent air conditioner. Discover the ideal placement to maximize cooling efficiency and create a comfortable environment inside your tent.

Installation Made Easy Follow a step-by-step guide on setting up your tent air conditioner. From securing it in place to connecting power sources, our instructions guarantee a hassle-free installation process.

Maintaining Your Tent Air Conditioner

Cleaning and Storage Tips Ensure the longevity of your tent air conditioner with proper cleaning and storage practices. Learn the essential maintenance steps to keep your device in top-notch condition for future camping trips.

Tent Air Conditioner: An Essential Camping Companion

A Cool Night’s Sleep Experience the luxury of a cool and comfortable sleep in your tent. Our guide highlights the importance of a well-regulated temperature for a restful night amidst nature.

Camping Beyond Summer Unlock the potential of extending your camping season with a tent air conditioner. Learn how these devices make it possible to enjoy the great outdoors in various weather conditions.

FAQs – Your Burning Questions Answered

How does a tent air conditioner work?

Discover the science behind tent air conditioners and how they effectively cool the air within your tent.

Can I use a tent air conditioners with any type of tents?

Explore the compatibility of tent air conditioners with different tent types and sizes, ensuring you find the perfect match for your camping setup.

Are tent air conditioners noisy?

Learn about the noise levels of tent air conditioners and how to choose a model that ensures a peaceful camping experience.

What power source do tent air conditioners require?

Understand the power requirements of tent air conditioners, whether they run on batteries, solar power, or external generators.

Are tent air conditioners suitable for all climates?

Explore the versatility of tent air conditioners and how they adapt to various climates, providing comfort in both hot and cool weather.

Can I use tent air conditioners in a camper van or RV?

Discover the flexibility of tent air conditioners, and find out if they can be utilized in camper vans or RVs for added comfort during travel.

Conclusion: Stay Cool, Camp Cooler

Elevate your camping experience with the cool comfort of tent air conditioners. From understanding their essential features to mastering the setup process, this guide equips you with the knowledge to turn every camping trip into a refreshing adventure.

Anchor Group: Elevating Your AC Experience. Your trusted source for OEM and aftermarket AC parts and tools. Discover exceptional value, convenience, and service.

https://www.acparts.cn/product-category/parking-cooler/

Introduction

In the intricate world of auto air conditioning parts, Anchor Group stands tall as a trailblazer, offering a diverse range of high-quality OEM and aftermarket components. This comprehensive guide delves into the realm of automotive air conditioning, exploring the excellence of Anchor Group’s offerings, from wholesale to specialized parts, and unveils why we are poised to dominate as the preferred car aircon parts supplier.

Exceptional Value Proposition

At Anchor Group, our commitment to providing exceptional value, convenience, and service is unmatched. Over the years, we have meticulously built a reputation for delivering top-notch results. Our success is a testament to our unwavering dedication to great discipline, effective communication, and streamlined processes, ensuring that every customer interaction is marked by professionalism and reliability.

A Product Range of car aircon parts supplier

As a leading supplier of OEM and aftermarket AC parts and tools, our inventory caters to a wide spectrum of vehicles, ranging from passenger cars and coach buses to heavy-duty trucks. Our automotive air conditioning parts wholesale service ensures that clients have access to a comprehensive range, making us the go-to destination for all their AC needs.

Auto AC Fittings: Precision in Every Connection

One of our standout offerings is the array of auto AC fittings meticulously designed for precision and longevity. These fittings play a crucial role in maintaining airtight connections within the air conditioning system. Crafted to withstand diverse driving conditions, our fittings contribute to the overall efficiency and performance of the AC system.

Aftermarket Truck Air Conditioners: Exceeding Expectations

Our commitment to versatility is exemplified through our aftermarket truck air conditioners. Tailored to exceed original specifications, these units offer a cost-effective solution without compromising on quality. Providing robust performance and durability, Anchor Group’s aftermarket truck air conditioners are engineered to stand the test of demanding conditions.

Automotive AC Condensers: Size Does Matter

Understanding the varied needs of our customers, we supply automotive AC condensers by size. This tailored approach ensures that our clients can easily find components that seamlessly integrate with their specific vehicle models. Our commitment to variety and specificity in product offerings sets us apart in the competitive landscape.

Carrier Bus Air Conditioning: Setting the Standard

In the realm of heavy-duty transportation, Anchor Group’s Carrier Bus Air Conditioning solutions set industry standards. Engineered for robust performance, these systems ensure optimal comfort for passengers during their journeys. From cooling efficiency to noise reduction, our bus air conditioning solutions redefine the travel experience.

Conclusion: Redefining Excellence in car aircon parts supplier

In conclusion, Anchor Group emerges not just as a supplier but as a partner in the automotive air conditioning journey. Our commitment to professionalism, a wide-ranging product catalog, and a customer-centric approach position us as the preferred choice for those seeking excellence in car aircon parts supplier.